Ever since its inception in 1980, Thermax-Enviro has been engaged in the design and manufacture of Fabric Filter System with different configurations to suit different applications. The product range on offer today convers Pulse Jet Bag Filters and Reverse Air Bag houses both structually supported free-standing on- line and modular off-line type units as also insertable type units.

A basic precept of Thermax has been the pursuit of quality in every product or system the bears the Thermax Stamp. This pursuit of quality is especially important in fabric Filter Systems- Where attention to application engeering, design detail and quality of fabrication acn means the difference between outstanding performance and medicore, high maintenance service. Be it process applications like boilers, furnaces, kilns and mills , or material handling nuisance venting catering to more than 50 different types of dust Enviro has been there before.

Thermax has, over the years, absorbed fabric filtration technology from two leading organizations of theirtime- Zurn Industries Inc. USA & General Electric Environmental Services Inc. USA- and progressively build on the same with in house application application engineering Strongly supported by field trials.

On Line: In an online bagfilter, bag are cleaned row by row, even while the dust laden gas is filterd concurrently. The Sequence of cleaning is controlled automatically by a sequance controller. The operates the assembly of solenoid and pulse valves which direct the air flow into the mainfolds. The holes are jig drilled for perfect alignment with the venturi center for achievinf maximum cleaning efficiency.

On line: It incorporates the advantages of a pulse jet bag filter as well as that of a reverse air baghouse. Each compartment is similar to an online pulse jet bag bilter. The cleaning process consists of sequentially isolating each 8compartment and then cleaning is suitable for light and fine dust where occurence of fluidization is a distinct possibility. Generally the Offline Bag Filter is employed for Larger gas volumes.

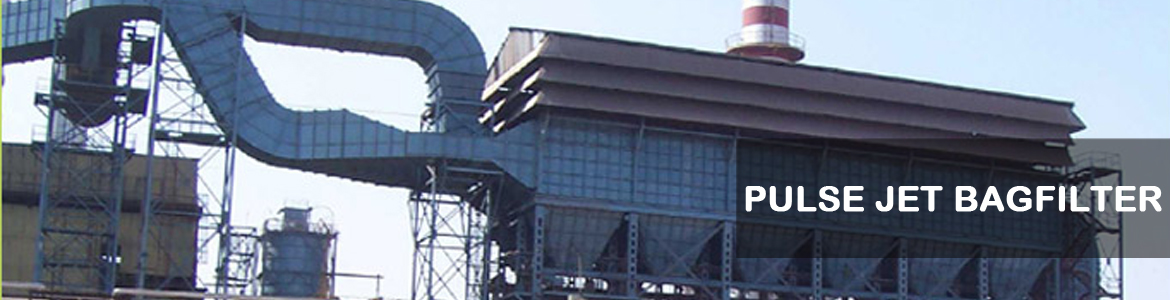

The pulse jet bag filter in its most rudinentary form bassically cinsists of the filtration elements housed in a casing. Below this casing is a hopper with a discharge valve , to continuously removes the dust that is collected on the bags. The Entire unit is supported from the ground on structural legs. A caged ladder provides access to the top of the unit for maintenance.

The dust laden air enters through the hoppers by suction (normally) or( positive pressure). The heavier dust get carried upward to the bags.

Transfer point involving two conveyors or from one conveysor to/ from other material handling equipment often involve isolated point(s) where free standing bag filter (a) can be an expensive proposition. Space availability on ground is also an issue at times. Typically, these insertable bag filters units are devoid any hopper. The unit can be suitablel positioned on the conveyor directly. On pulsing, Dust falls back onto this conveyor, thus avoiding a need for a separate dust discharge hopper.

Depending on the height of fall of dust, two such insertable bag filters may be required- one at the end of the discharging converyor and one on the reciving conveyor. When a single unit is used, it is normally on the recieving conveyor- as shown in the adjoining figure-this being where generation of dust is higher due to impact. These type of units are also optimal solutions for venying of bins/ silos/ hoppers.