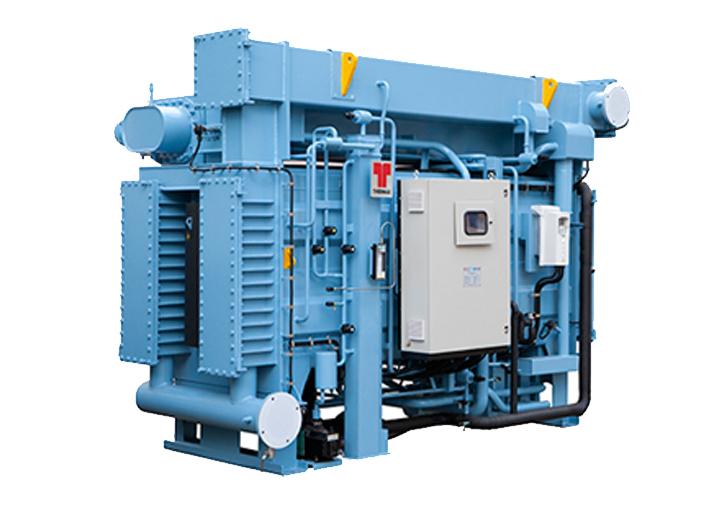

The Cooling SBU of THERMAX promotes vapor Absorption Chillers as a cost effective and environment friendly alternative to electricty driven compression chillers.

It offers experts solutions in process Chilling & Air Conditioning for Industrial as well as commercial applications. Cooling SBU'S strength lies in customized solutions as per the requirement of custmers.

Unlike Electrical chillers, Absorption Chillers are powered by heat. These machines can run on a variety of heat sourse, e.g. steam, hot water, liquid/gaseous fuels, exhaust gases and/or a combination of above.

Vapor Absorption Technology from Thermax is at work for clints in more than 50 industries including Pharmaceutical, Chemicals, Fertilizers, textiles, Petrochemicals, food & Beavrages and automobiles industries as well as Hotels, Commercial Complexes, Shopping Complexes, Office Buildings Educationals Institutes, Airports and Cinema Halls.

Manufacturing Cpabilities of Thermax's Cooling SBU are confirmed by the fact that, over the years, Thermax has installed numerous machines in more than 70 countries including USA,Germany, Sapn ,UK, Italy,UAE,Saudi Arabia, India, China, Australia, Thailand, Philippines,Malaysia,Russia and Nigeria with the products conforming to the respective country satandardes like ETL, CE, TUV, DNV, ASME etc. Tharmax has its fully owened subsidiaeies namely Thermax Inc. in USA, Tharmax Europe Limited in UK and Thermax (Zhejiang) cooling and heating Engg. Company Limited In China.

Thermax belives in efficient and responsive services to its clients and exhibits in its way of bussiness, by giving optimal and quality solutions and achiving customer delight. Thermax has a world wide sales, services and destribution network to fulfill the needs of it,s valuable customers.

The uniqe two stage technology ensures the lowest specific heat input requirement resultin in lowest heat and water consumption.

Two stage evopration also gives to 5 to 7% higher COP than convantional single stage evopration technology.

Unique state-of-the-art constantration control and display that virtullay eliminates and crystallisation and its is distincly different from the auto decrystllization offered by other manufactures. this permits the VAM to run smoothly even at 10degree C (50 degree F) cooling water in let temprature.

Isolation values seals for vaccum application and boiled pump maintenance without any loss of vaccuum in the system due to exposure to atmospare.